Why your assets need predictive maintenance

The benefits of predictive maintenance

In the past few years, the predictive maintenance market size has grown very rapidly. In fact, it is estimated [1] to have grown from about £1B in 2016 to about £5B in 2021 and it is predicted to further grow to about £28B by 2026.

The reason for such a quick growth is that predictive maintenance is addressing the needs of Industry 4.0, which is focused on efficient, data-driven, and automated ways to carry out maintenance timely, more efficiently and cost-effectively. Leveraging on the presence of appropriate data infrastructure, this has been possible thanks to AI and Internet of Things (IoT), which enable predictive maintenance solutions to generate a high return on investment, making it also possible to amortise the investment quickly (often in less than a year [1]). In addition, the full integration of these solutions into enterprise software and systems enables them to (timely) deliver actual value to the end-users.

As a result, there is high demand for predictive maintenance solutions by both companies that have already moved from traditional reactive/preventive maintenance to AI-driven, predictive maintenance and those that are transitioning or are planning to do so.

Some of the clear benefits that predictive maintenance offers are:

- Cost reduction

- Life extension of machinery, processes, and infrastructures

- Improvement of asset availability, i.e., improve productivity, decrease (production) downtime, and improve safety

- Minimising failures and avoiding those with extreme consequences

- More efficient time management

- Reduction of environmental impact

- Enabling of data-driven decision making

While the levels of these benefits may change across sectors, their existence is widely established.

Having identified the type of benefits brought by predictive maintenance, we now focus on a few case studies to explore them and their levels in different sectors.

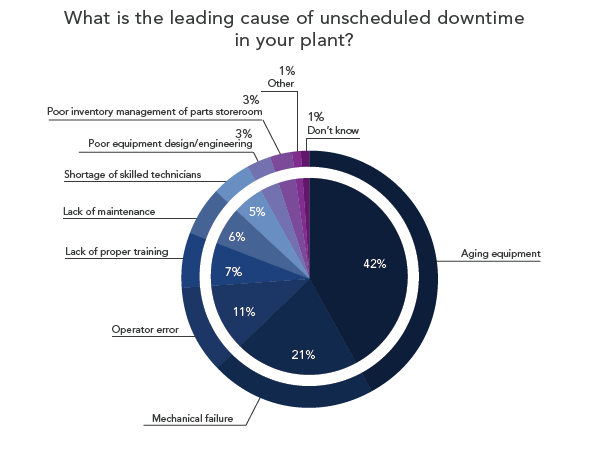

Predictive maintenance in manufacturing plants

Manufacturing is one of the largest sectors for predictive maintenance applications. In fact, manufacturing plants must carry out maintenance of their machinery to keep production going and meet product demand. Often companies in this sector, about 50% of the plants [2]) use a reactive (a.k.a. run-to-failure) maintenance approach, according to which maintenance actions are triggered by events such as the breaking down of machinery components, mechanical failures, ageing equipment, and human errors. A view on the most typical causes for unscheduled downtime is provided by the following figure [3].

Figure 1: Most common causes of unscheduled downtime [2] (Figure from [3]). The figure represents results from a survey of 200 qualified individuals in the US and it is used here as a representation of a widespread situation at an international level.

In these situations, unscheduled plant downtimes are unavoidable, and their negative impact (such as revenue loss) can only be reduced through fast reactions to solve the issue at hand.

Leveraging data (very often collected with IoT devices), Cloud Computing, Machine Learning and Data Science, predictive maintenance can, among other things, predict system failures, monitor the ageing of equipment for timely replacement and guide human actions to prevent human error. In this way, unscheduled downtimes can be reduced significantly. For instance, predictive maintenance in the manufacturing plants sector was already linked to a 50% reduction in maintenance costs and to a 55% reduction in unexpected failures [4] in the early 2000s.

In addition to reactive maintenance, manufacturing plants often also use a preventive maintenance approach. We will focus on the latter in comparison with predictive maintenance in the next case study, as this approach is widely used also in many other (industry) sectors.

Predictive maintenance in mobility

Maintenance is heavily required in the Mobility sector, where it encompasses several areas, i.e., from vehicle-components provisioning and replacement, through infrastructure and asset management, to people (staff and civilians) safety.

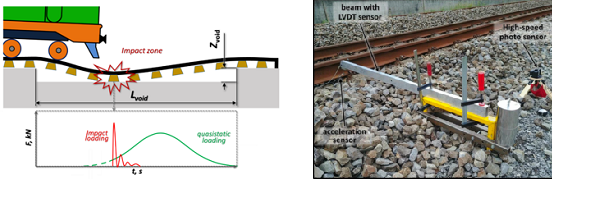

Focusing on the railway sector, in particular, maintenance is used for preventing and/or solving issues with mobile, linear, and fixed assets that can lead to downtime or service delays, such as:

- Fleet security, safety and/or quality component failures

- Presence of track voids

- Rail breaking

- Ageing/outdated signalling system and equipment

- Overhead line equipment failures

- Weather-related issues such as flooding, landslips, ice, and snow

Figure 2: Figure 2: left-hand side: schematic representation of the dynamic impact of sleeper and ballast in the presence of a void zone (Figure 2 in [5]); right-hand side: experimental setup for rail deflection and acceleration measurement, with a high-speed photosensor, beam with linear variable differential transformer and acceleration sensor (Figure 2 in [6]).

In this sector, preventive maintenance is a common approach, especially since many of the assets and their components are highly regulated for safety reasons. However, this approach can be risky, sub-efficient, and a source of unnecessary extra cost. In fact, what if the track-void formation’s timescale or the lifecycle of a key component of a train (such as the breaks) is shorter than the frequency of the scheduled maintenance checks? Track voids may form in between periodic checks. Similarly, train components may wear out and fail in between periodic checks. These scenarios will have negative consequences such as train cancellations, (knock-on) delays or, in the worst case, accidents.

On the other hand, if the lifecycle of train components and the track void formation timescale is longer than the frequency of the maintenance checks, service failures will be avoided but the train and track cost managements will be inefficient due to more-frequent-than-necessary maintenance checks. In addition, unnecessary maintenance downtimes will be scheduled, possibly causing further train cancellations and delays.

Conversely, predictive maintenance solutions are more suitable to tackle these problems. In fact, their usage of IoT devices for (real-time) data collection and usage in conjunction with AI methodologies enables users to:

- prevent downtimes and failures more efficiently

- react more rapidly when disruption cannot be prevented

- better minimise damages and costs

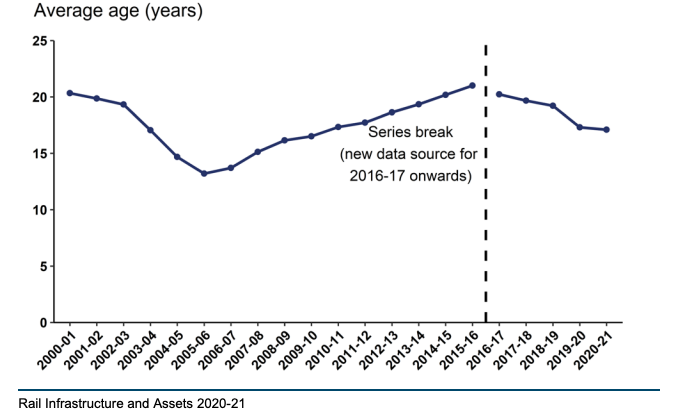

Figure 3: Yearly average age of rolling stock over time (Figure 3.2 in [7]). Is this quantity a good indicator of rolling stock conditions? For instance, the introduction of new rolling stock may lower the average age and be interpreted as an improvement in the overall rolling stock conditions. However, it could also be a sign of a sub-optimal (reactive or preventive) rolling stock that could cause the need to purchase and introduce new rolling stock, hence generating new, unnecessary expenditures that predictive maintenance could have avoided or delayed.

The importance of choosing the optimal maintenance approach becomes more prominent if it is considered against relevant facts and figures. Therefore, in order to highlight this importance, we report below some facts and figures of relevance about the UK railway sector (mainly for the 2019-2020 period, to exclude influence from Covid-19 pandemic):

- In the 2019-2020 period, the UK rail industry’s (Network Rail) expenditure for maintenance amounted to about £1.7B, equivalent to about 20% of the entire Network Rail expenditure [8]

- In the same period, UK train-operating companies paid about £90M in rail passenger compensations [9]

- Again in the same period, about 6.4M delay compensation claims were submitted by UK passengers when eligible for claim submission [10]

- The figures in the previous point should be assessed considering that: i) in 2020 about 55% of passengers experienced a delay eligible for compensation; ii) 25% and 51% of these passengers were unaware they could claim for their delay and did not claim because the amount was not worth the effort, respectively [11]

- In 2019-2020 the average age of rolling stock was 17.3 years [12]

This information allows us better contextualise the potential benefits that predictive maintenance can offer. For instance, even just a 10% reduction in the UK railway sector’s yearly expenditure for maintenance could save about £200M yearly, money that, for instance, would more than cover the about £100M yearly expenditure generated by rail passenger compensations.

However, in addition to sector-specific considerations, more general ones will be made below, highlighting the advantages of using predictive maintenance in any sector.

Why should a business choose predictive over preventive and reactive?

Predictive maintenance is used to carry out several and different tasks across different sectors, many of them being related to predicting system failures and estimating remaining useful life of equipment ahead of time. Predictive maintenance also assesses risks and prioritises actions accordingly to minimise negative consequences.

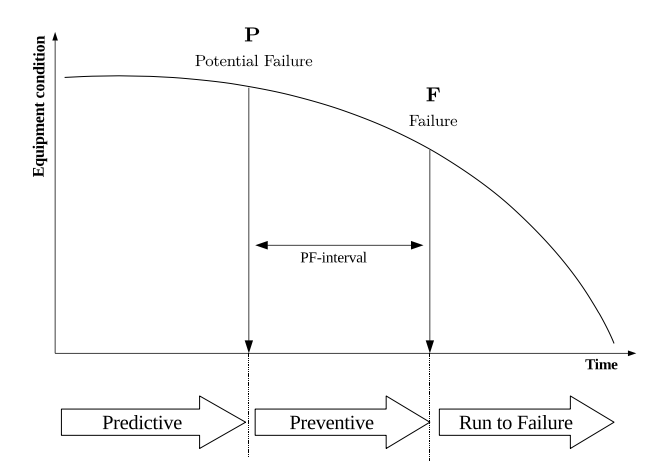

The advantages of predictive maintenance in industry are widely clear and, while we have described them in the context of manufacturing plants and railway, they are relevant to all sectors. It is true that the level of benefits generated by predictive maintenance may vary across them. However, general considerations based on where predictive, preventive and reactive maintenances locate themselves in the asset lifetime, can shed further light on why predictive maintenance is the ideal approach, in the presence of suitable data that are timely collected, processed, and served. The Potential Failure - Reliability curve comes to our aid.

Figure 4: Potential Failure (P-F) reliability curve in maintenance management (Figure 1 in [13]). This curve clearly displays the relative locations of the three different approaches to maintenance in the asset lifetime and hence enables to appreciate the different amounts of action and reactive power possessed by of each of them. In the presence of adequate data and data infrastructure, predictive maintenance clearly constitutes the optimal choice.

By visualising where each maintenance approach sits in this curve, it can be clearly seen that predictive maintenance has the best chances to prevent failures. In fact, thanks to the exploitation of historical (e.g.time-series) and/or real-time (via IoT devices) data to identify and learn patterns with ML techniques, monitor them and predict future occurrences, predictive-maintenance-driven actions start already when the equipment is in good conditions. In addition, automated and/or human actions are triggered before the potential-failure time interval. This significantly prolongs the equipment lifetime, extends the available time window for intervention, and drastically reduces the probability of system failure. Therefore, processes are more efficient, costs are reduced, risks are better assessed, and necessary actions are prioritised early to minimise negative consequences.

In fact, recent studies [14, 15] on the benefits of predictive maintenance performed by some of the major consulting services providers in several industry sectors (such as manufacturing, transport, ports, construction, energy & mining, oil & gas, chemicals & electronics and healthcare, to name a few) show that predictive maintenance solutions can drive 10-40% reduction in maintenance costs, 50% reduction in downtime due to equipment failures and 4-20% extension in machine useful lifetime.

Even achieving a small fraction of these figures can generate cost reductions that can be equivalent to the generation of new revenue streams and/or to increased product sales.

Kainos predictive maintenance solutions

At Kainos we provide AI-driven predictive maintenance solutions, but we also make sure that they are based on high-quality, well-governed, and carefully validated data within a suitable cloud-based data infrastructure, tailored to client’s processes and needs. Based on client’s position in the digitalisation journey and on the (business) problem to solve, our predictive maintenance solutions utilise a varied range of AI techniques (such as regression, classification, unsupervised clustering, and deep learning) while ensuring appropriate understandability and interpretability.

Learn more about how we can help your business

Discover how predictive maintenance can save your business time and money. Our Data & AI capabilities develop solutions suitable for all sectors and tailored to clients’ requirements. Get in touch to book a meeting with our predictive maintenance business development expert Greg Richards.

List of resources

[1] Predictive Maintenance Market Report 2021-2026, 2021, IoT Analytics

[2] 2021 Plant Engineering's Maintenance Study, 2021, Plant Engineering

[3] The Maintenance Function, Like Manufacturing Itself, is a Rapidly Changing Environment, 2021, Plant Engineering

[4] Plant Engineer’s Hanbook, 2001, edited by R. Keith Mobley

[5] Sysyn, M.; Przybylowicz, M.; Nabochenko, O.; Liu, J. Mechanism of Sleeper–BallastDynamic Impact and Residual Settlements Accumulation in Zones with Unsupported Sleepers. Sustainability 2021, 13, 7740

[6] Sysyn, M., Nabochenko, O. & Kovalchuk, V. Experimental investigation of the dynamic behavior of railway track with sleeper voids. Rail. Eng. Science 28, 290–304 (2020)

[7] 2020-2021 Statistical Release Rail Infrastructure and Assets, 2021, Office of Rail and Road

[8] 2019-2020 Statistical Release Rail Industry (Finance), 2020, Office of Rail and Road

[9] Rail Passenger Compensation Paid by Train Operating Companies, updated on 28/09/2021, Department for Transport

[10] 2019-2020 Rail Delay Compensation Claims Factsheet, 06/2020, Office of Rail and Road. See also corresponding dashboard

[11] Rail Delays and Compensation 2020, 10/2020, Department for Transport

[12] 2019-2020 Statistical Release Rail Infrastructure and Assets, 2020, Office of Rail and Road

[13] Davari, N.; Veloso, B.; Costa, G.d.A.; Pereira, P.M.; Ribeiro, R.P.; Gama, J. A Survey on Data-Driven Predictive Maintenance for the Railway Industry. Sensors 2021, 21,5739

[14] Predictive Maintenance 4.0, Beyonf the Hype: PDM 4.0 delivers results, 2018, PwC

[15] The Internet of Things: Mapping the Value beyond the Hype, 2015, McKinsey&Company